What’s new in APF WoodBeam 5.2

13 December 2021

WoodJoint and NextFEM. The new timber joints plugin

8 February 2022Designing the supports of a timber beam – WoodBeam to WoodJoint

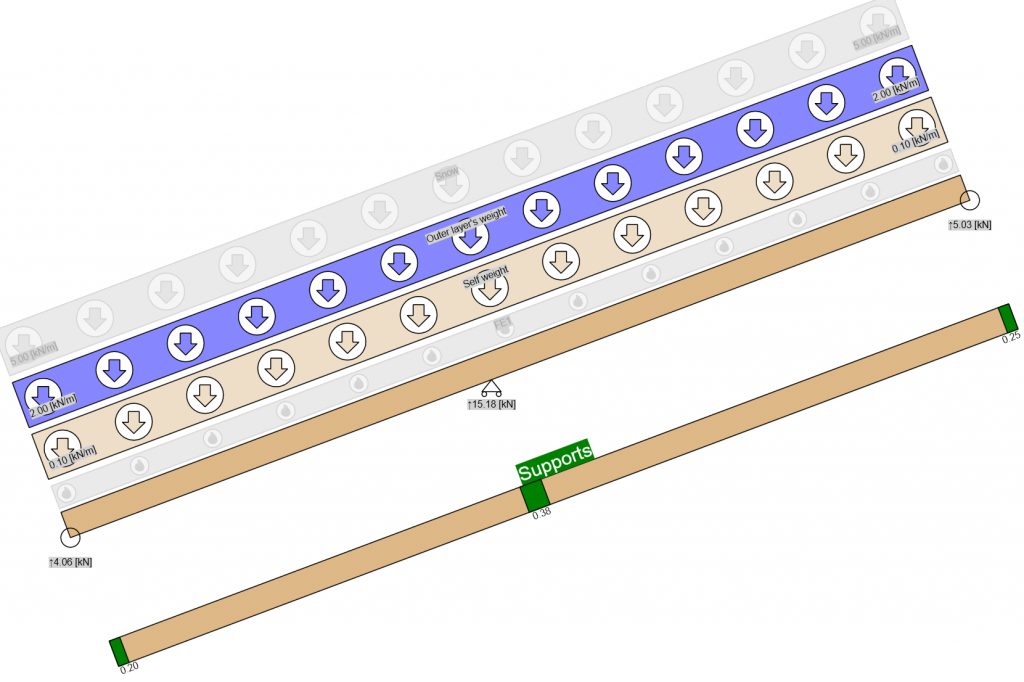

In APF WoodBeam it is possible to evaluate the constraint reactions but also to verify the support compression. APF WoodBeam allows to check the value of the compression perpendicular to the grain in correspondence of the supports, asking the user to specify the width of the contact zone.

When this type of check is not enough, it is necessary to export the information from APF WoodBeam to APF WoodJoint and complete the design of the connection. This procedure is performed with a simple command that exports the reaction forces in the different combinations of actions, the dimensions of the timber beam and the material properties.

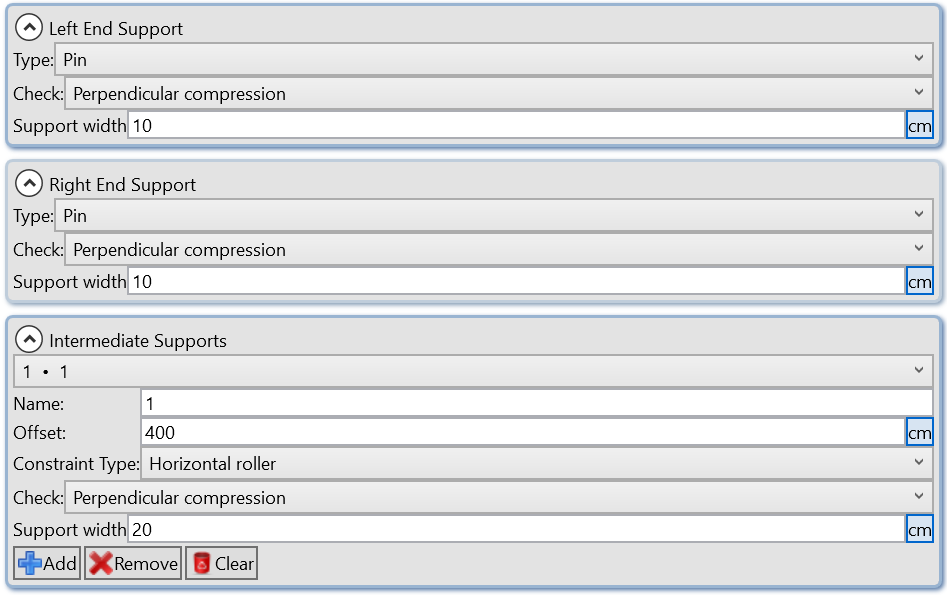

The check of the support’s reactions in WoodBeam

For the simplest cases the analysis can be completed in APF WoodBeam which is able to check that the compression at the supports is within the limits established by the Technical Standards

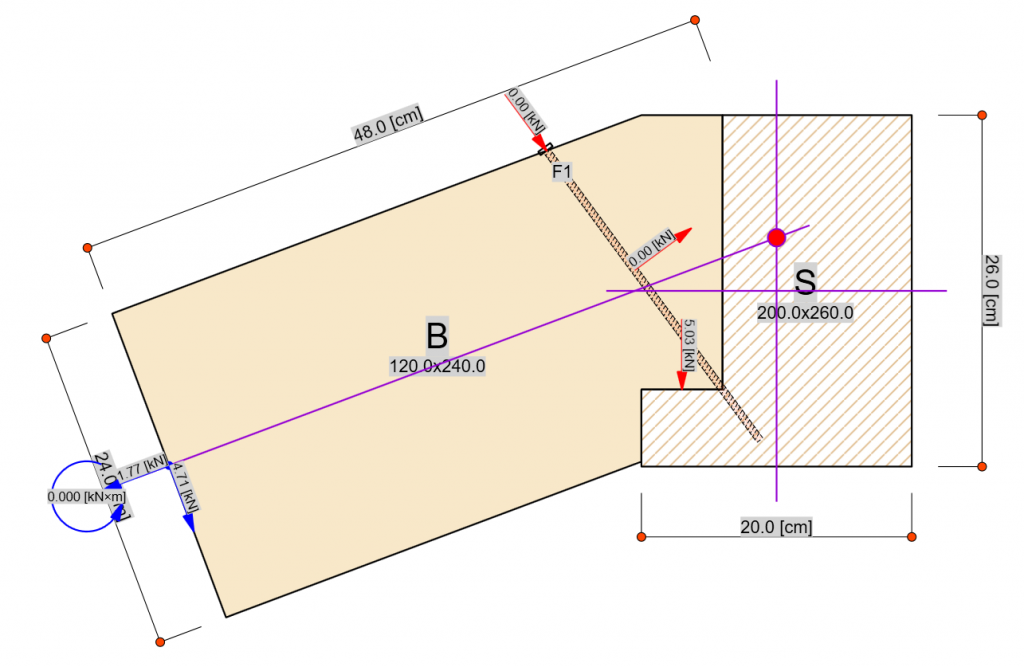

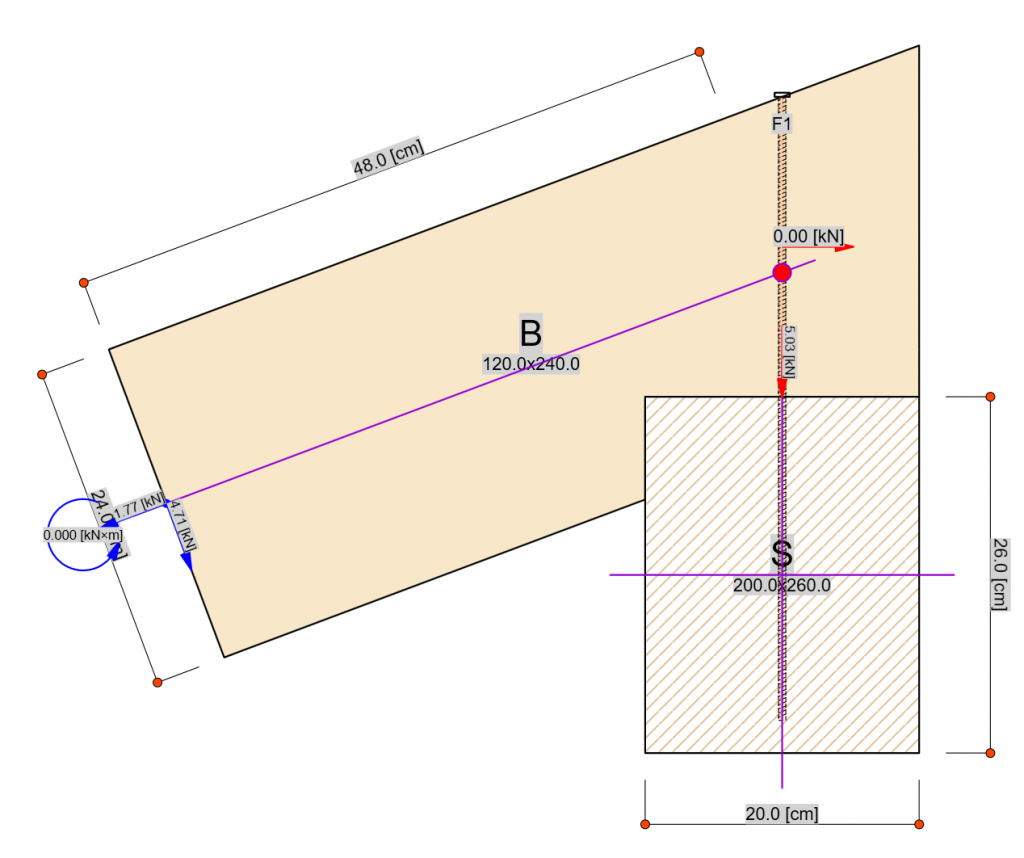

The following images illustrate the input of information regarding supports in APF WoodBeam and how the perpendicular compression check is represented.

In APF WoodBeam, checking beam strength at supports is optional. When enabled, the check is immediate for all combinations of actions and is instantly updated as loads or support widths change.

Exporting information to WoodJoint

Sometimes the simple check done in APF WoodBeam is not enough to complete the verifications needed for the design, because the connections require the use of screws (or other fasteners) or steel angles, notches and other solutions. For these cases APF WoodBeam allows you to export the information to APF WoodJoint with a simple command. The exported information includes the combinations of actions and the forces in the beam near each support, the size of the timber beam cross section and the material used.

Other information must be entered directly in APF WoodJoint, such as the exact type of connection to be designed and the fasteners to be used. The user has indeed great freedom in the design and can take advantage of all the options made available by APF WoodJoint. All supports in the WoodBeam model are exported at once within the same WoodJoint file as independent “nodes” in the same project.

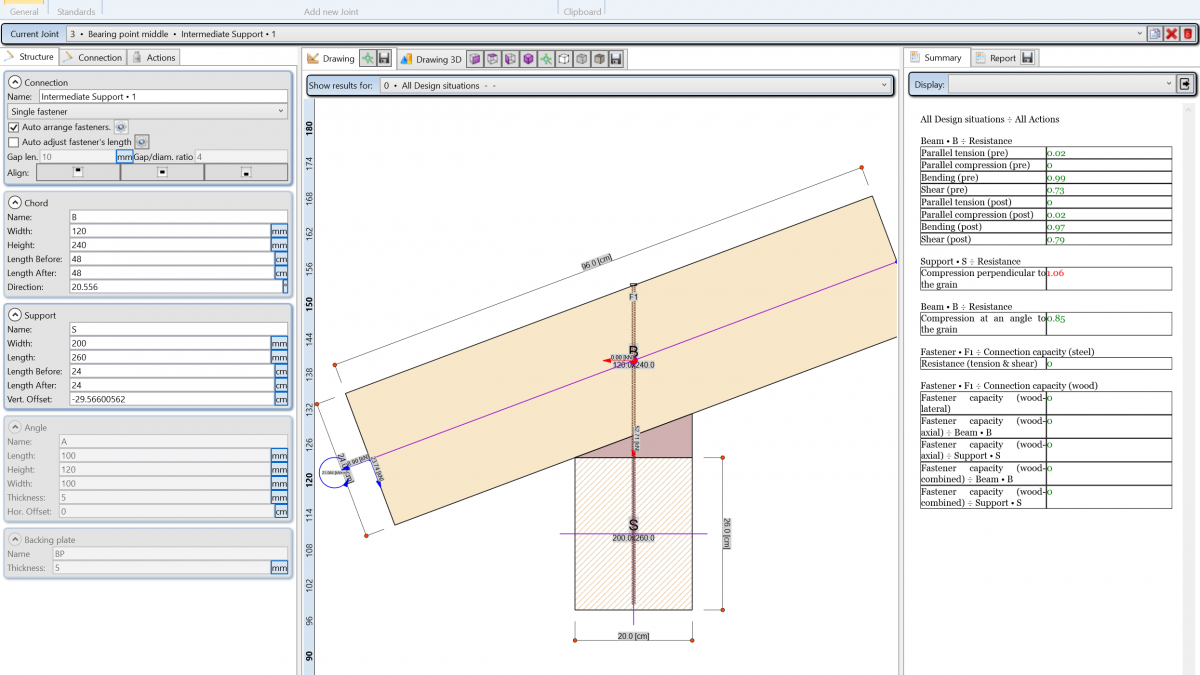

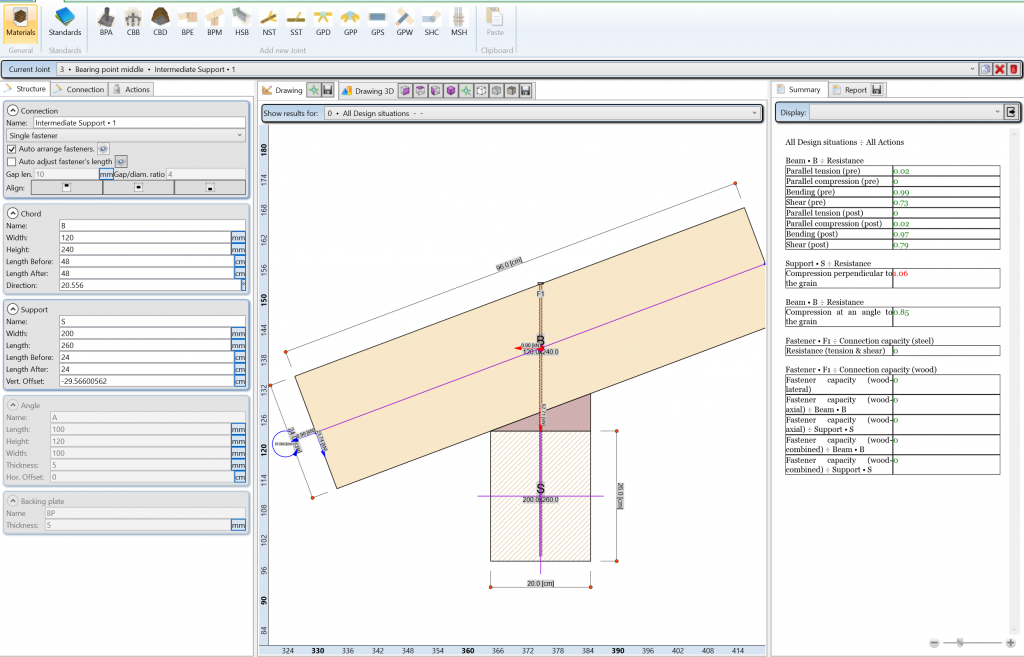

Below there is an image of the button that allows exporting from APF WoodBeam to APF WoodJoint and an example of an intermediate support just exported.

The design of a support in WoodJoint

The export from APF WoodBeam proposes a node configuration but does not constrain the user. For example, in the case of an end support, it is possible to realize the connection with crossed screws, with a bearing and a screw, with bolted brackets (with or without backing plate) or with a dovetail notch.

APF WoodJoint keeps the information received from WoodBeam but allows you to change the connection configuration to suit your needs, until you get a satisfactory design.

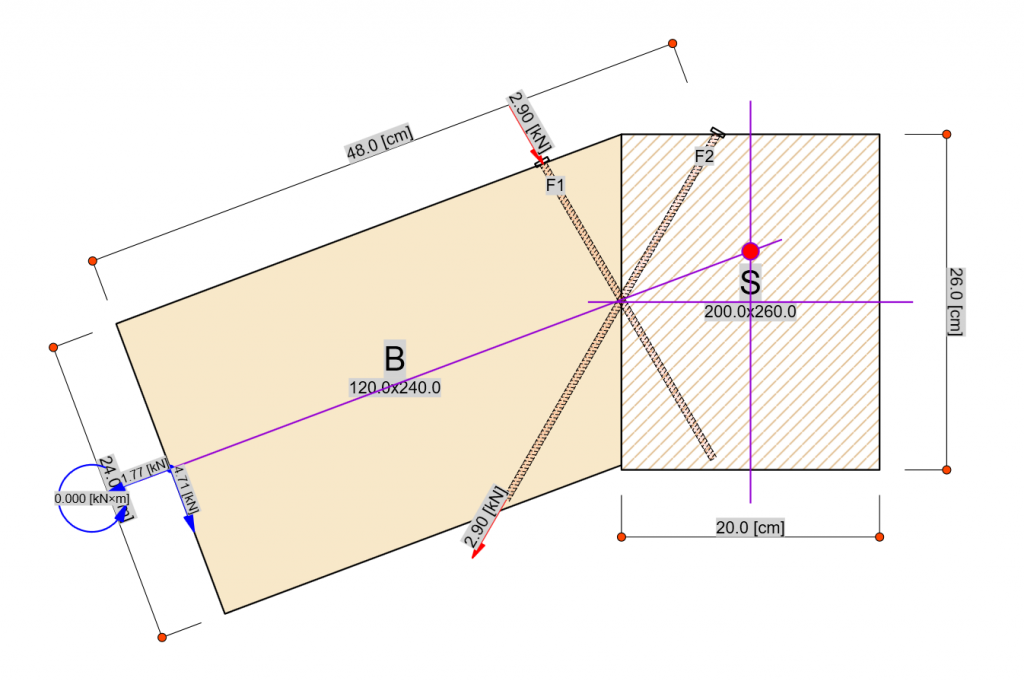

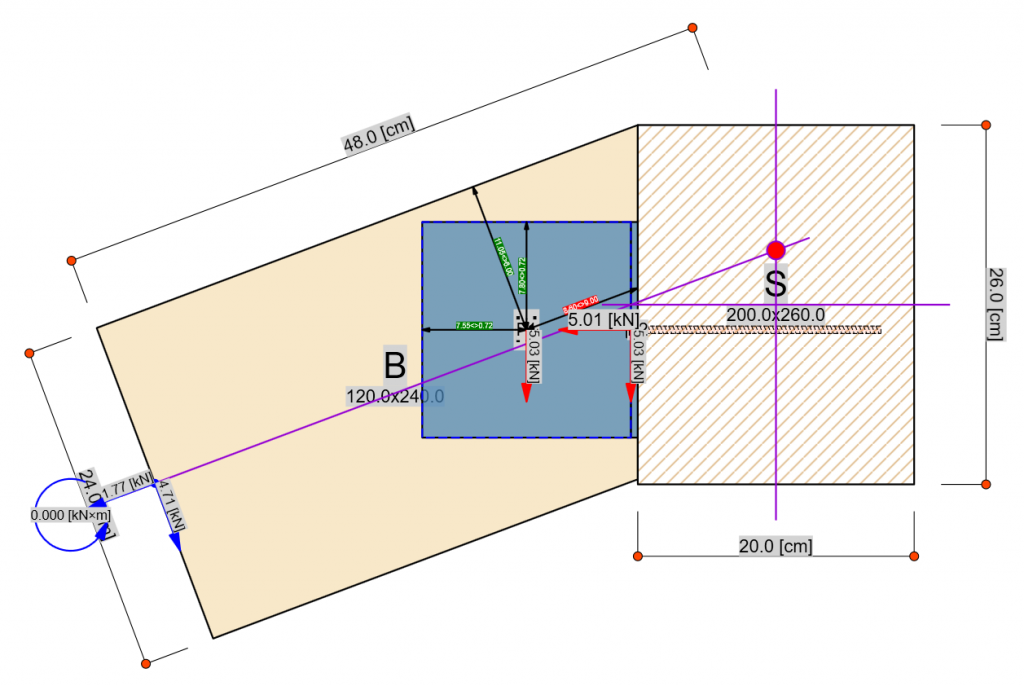

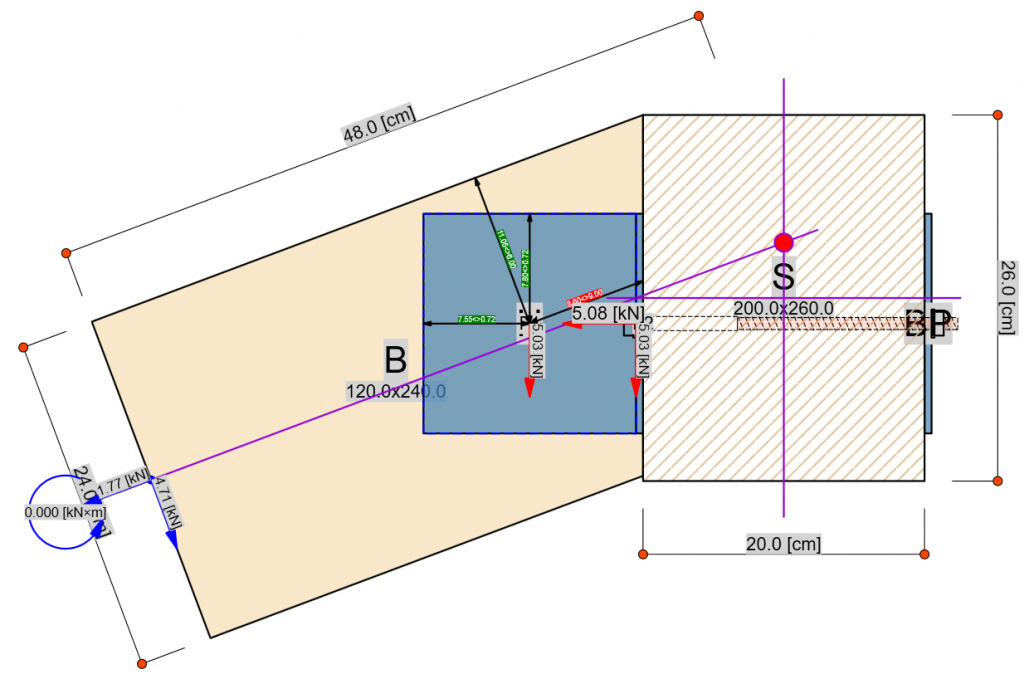

Some images of alternative configurations of the same connection imported from WoodBeam are shown. All configurations represented are subject to the same actions.

In this way APF WoodJoint allows you to complete every aspect of the structural design of timber members designed with APF WoodBeam.